Cartridge dust collectors were developed using an existing filter technology utilized in the automotive and heavy machinery industries: the diesel engine intake filter cartridge. This cylindrical filter design relies upon a pleated filter media design to offer greater filter media area within a smaller space. This design is useful for certain types of dirty air streams, specifically those with low filter loading volumes or with fine dusts. Larger dust particles, abrasive dusts, and stringy/sticky dusts are not recommended for cartridge dust collector designs.

Typical Filter Cartridge

Unfortunately, there are a few big dust collector companies which rely on making filter cartridges a commodity item that you would need to buy on a regular basis. They are primarily filter manufacturers, and view the Cartridge Dust Collector as another means of selling overpriced filters to a captive market. Although they offer inexpensive dust collectors, these big blue or green boxes frequently need new filters. This design consideration is a means of securing a dedicated source of income from their customers, who are forced to buy proprietary filters with gimmicky shapes or features that don’t work. This “HP Printer Ink” business model is not fair to you, the customer, as better cleaning systems are available which prolong filter life and reduce your overall cost of ownership. We offer competitively priced replacement cartridges for those brands when possible, but we will not sell their equipment.

Cleaning of cartridge filters is accomplished by reverse air flow through compressed air, usually in the form of pulse jet cleaning systems. The concept is nearly identical to baghouse pulse jet cleaning systems, with a quick pulse of compressed air momentarily reversing the flow through the filters and shocking the dust off the filter media.

ENCLOSED CARTRIDGE-BASED DUST COLLECTORS

A.C.T. Dust Collectors offers a competitive range of modular Cartridge Dust Collectors, and offers a unique abrasive dust inlet plenum. By adding a collection area to the inlet where the dust enters vertically downward, the build-up of dust provides an area for otherwise-harmful dust particles to collect. At first the particles are collected in this “dead zone” with no means of collection; as the dust builds up to the point it can spill over into the collection hopper it provides an impact buffer which slows the larger dust particles to harmless velocities. This reduces overall operating costs by relying less on the filters for collection, and by avoiding costly abrasion to the filter media.

A.C.T. Cartridge Collectors – (2) 4-48 models

COIMA USA offers a range of indoor/outdoor cartridge dust collectors in their F Series, FC Series and FB Series lineup (the -380 and -450 models use cartridges while the -250 and -320 use sleeve-type filter bags).

PORTABLE & SMALL FORM FACTOR COLLECTORS

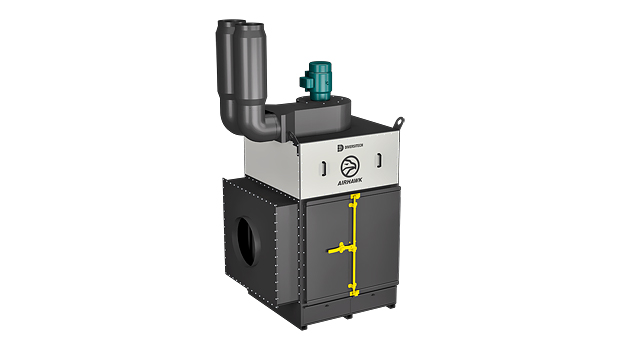

Diversitech produces a range of smaller cartridge based collectors as the FRED Jr & FRED Sr series, and now offers a mid-range modular design as the AIRHAWK series. Many of the FRED series collectors are also available as portable models with optional extraction arms. These provide an economical solution for small shops or for work done on large and awkward work pieces where stationary collection systems cannot easily provide sufficient extraction. ProVent offers the SideKick PSK, a portable collector with one extraction arm (optional) and a tiny footprint. Movex offers the MF Roll-Around collector for maintenance welding operations, and the ultra-portable handheld SF Collector for difficult to reach spaces.

Diversitech FRED Jr

DOWNDRAFT TABLES

When grinding, sanding, finishing and other processes require a ventilated work surface a cartridge-based downdraft table is the ideal solution for a clean and healthy workplace. Any material removed from a work piece is then captured by the air flowing into the table’s work area and then trapped by the cartridge(s) underneath, or drops out of the airstream into the dust collection trays underneath. Pneumatic cleaning systems (available on most models) clean the cartridges, and the waste material is collected for disposal in removable dust trays at the bottom of the table. Adding optional casters to certain downdraft tables converts them into mobile units, offering flexibility for difficult work pieces or workshops where grinding or finishing is not done withinin a dedicated section of the workshop. We offer ProVent Intercept PDB benches, Diversitech DD Series tables & workstations, and COIMA USA BAP Series tables.

Diversitech DD-3X8

In some cases it may make more sense to utilize Ducted Downdraft Tables and a central dust collector system. These tables have a grated & ventilated work surface but no integral dust collection. The duct outlet is placed on the side, rear, or underneath the table, and ductwork connecting the table to the collector provides the extraction for the work surface.

LASER PACKS

Over the past several years we have seen a growing trend in dedicated cartridge dust collectors for designed for Laser Cutting and Plasma Cutting systems. We offer competitive solutions from Diversitech, A.C.T. and Movex for these applications. These systems are located near the CNC cutting system with sufficient ducting that the vapors have time to cool and condense into a dust which can be collected through cartridge filters. We strongly recommend the addition of a spark trap device to the ductwork. This prevents hot embers from entering the collector (a serious fire hazard), and the added turbulence has a bonus effect of increasing the rate of vapor precipitation as dust. A properly configured Laser Pack can make a drastic difference in visibility and air quality during the cutting process, and reduction in dust accumulation in the vicinity. Contact us for more information if you are looking for a dedicated solution for your CNC cutting equipment.

A.C.T. LaserPack 4

ENVIRONMENTAL CONTROL BOOTHS & MODULES

Often dusty air is a difficult and pervasive problem in some work environments, such as grinding or finishing of large items or surface areas, and a dedicated environmental solution is required. Environmental Control Booths & Modules offer a means of filtering large quantities of air at a given point, allowing for a regular cleaning of the air within a confined space. The modules can be placed along one wall of a room, opposite to the opening, to collect dust from the air as it flows from the open side towards the collectors. This directed flow of air allows for a regular cleaning process to occur and maintains an environmentally clean and safe workspace.

ProVent Enviro-Cell

If a dedicated room is not available, an enclosure is provided as an option to ensure that all of the dust produced during the grinding or finishing processes is contained and collected in the most efficient way. These include a number of options, including fully-enclosed areas with doors and return air curtain at the front of the enclosure to promote desired airflow through the work space.

ACTion Booth

WELDING SMOKE CONTROL

A similar means of cleaning air in larger work areas where welding occurs can be accomplished by ducting the inlet and outlet of a cartridge collector to direct airflow across the work area. The ducts at each end feed to/draw from a series of diffusers and grilles, providing a controlled cross-flow of air. Welding smoke has a tendency to stratify at a certain height within a workspace; by locating the diffusers and grilles at that elevation above the floor the welding smoke is effectively removed from the work space, providing a cleaner and healthier workplace for your employees.

We recommend Diversitech AIRHAWK and A.C.T. Cartridge dust collectors for welding smoke control solutions, including as a central collector for a network of welding arms.

Environmental booths and welding smoke collection systems are rated by the number of air exchanges per hour in a given space. That is the amount of air which can be moved through the workspace and cleaned by the collection systems in one hour of operation. For example, a work area that is 20’ wide x 30’ long x 20’ high has a volume of 12,000 cubic feet. A collection system with a nominal capacity of 2,000 CFM will clean 12,000 cubic feet in 6 minutes. This solution provides 10 air exchanges per hour, which is adequate for light to moderate welding.